Situation

It is well known that human factors issues, which can be causal factors, are involved in aviation accidents. The purpose of ATA chapters and guidelines is to set forth voluntary standards suitable for adoption by companies engaged in aircraft and aircraft component maintenance for developing and maintaining a maintenance human factors program to enhance safety and aid maintenance personnel in preventing aviation incidents.

Solution

During my mission with the R&T team @AIRBUS, working side-by-side with their teams. We went through multiple iterations to understand their existing documentation, how it's managed and used.

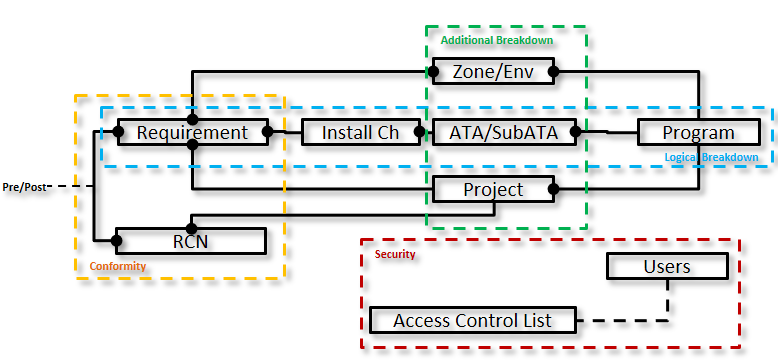

- Concept & Design: Identifying the key ressources and business processes to use, model them and design an agile workload planning.

- Prototyping: During the early phase, prototyping was done along with writers and designers with spreadsheets and presentations. Once we evaluated the variety of contexts, including semantics, design, UI/UX, we used RAD tools to provide a real situation working PoC.

- Material, process and verification: Since the processes were complex, we discovered new ways to shrink them, and other ways to automate the most of them. We went through another iteration of coding, starting fresh to deliver a stable solution.

- Go Live: Rollout of the solution, in three steps:

- For writers in order to gather the information

- For designers to use it with their CAD tools

- For the Change Board (for in-process design rectifications, relaxations and request change notes)

For designers, it enables faster access to the right and up to date information, with schematics, explanations, 3D models and powerful criteria-based search engine.

Next Steps

- More documents cascading from the top level ATA chapters could be integrated. We performed tests with Technical Design Directives, Means and Tools and other manufacturing documents. We saw a real potential especially for tracking changes down or top stream.