Prototype Description

From nose to tail, and air to ground, the aviation industry is constantly developing new technologies to advance all aspects of flight. It is important to explore new technologies that enhance the user experience of everyone that touches flight with new solutions that make their jobs easier and more efficient. For instance, AIRBUS has not only been testing voice recognition for pilots in the cockpit but has developed a voice application to support maintenance operations.

Airbus is increasingly using the help of computerized co-workers capable of functioning safely alongside their human colleagues.

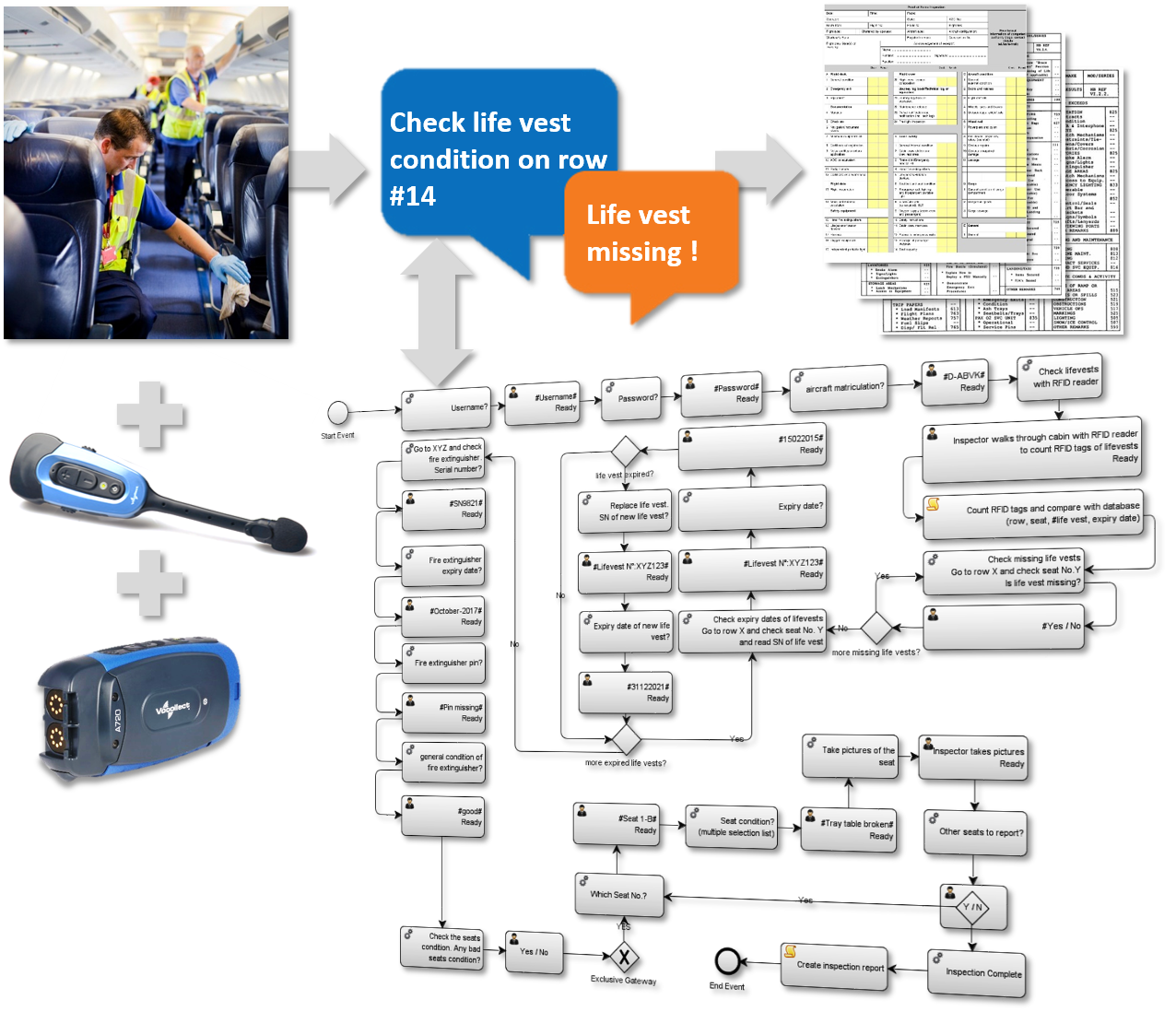

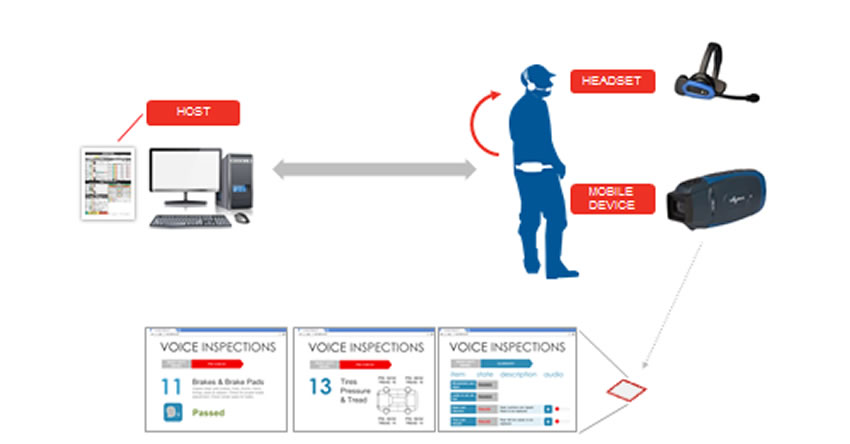

This solution supports cabin inspection line and check process by allowing mobile workers a mobile way to give instructions and collect data for cabin inspectors. The technology cuts down on the outdated back and forth data entry and look up time on a laptop, handheld device or paper forms and lets maintenance personnel speak commands and verbally input data findings directly into the system via a headset with a microphone. By using voice recognition, they are able to continue their work uninterrupted, greatly increasing the efficiency of operations.

This solution can also support component MRO, line maintenance and heavy maintenance for the aviation industry.

The technicians’ verdict

One of the most common questions is how the technicians respond to the solution: do they like it? Do they find their processes easier or more difficult to follow? How do they find the technology?

After all, it has completely changed their work processes, replacing the paperwork or smartphones with which they have become familiar. Initially, many technicians were hesitant to adopt it. However, they found the paper-based processes very time-consuming and inefficient, and once they began to use the new technology, they quickly realized that it had significant advantages – and made their working day much easier.

Lessons learned

As the implementations progressed through more AIRBUS sites, we gathered data and feedback to drive the solution’s success, including much about the critical change management process. We examined the technicians’ inputs and feedback early on, and gathered the high-performing technicians to advise us on which was the most optimized workflow. With this process the technicians were the ones leading and championing the implementation. Once the decision was made to go live at a site, we conducted classroom and on the shop floor training to ensure that the technicians were comfortable with the technology, and we kept people onsite after go-live to answer questions. After gathering that continuous feedback, we were able to complete time studies about before and after the implementation. These gave us tangible and measurable results.